Grinding Mills - Types, Working Principle & Applications

Grinding Mills - Types, Working Principle & Applications

The purpose of this article is to explain the usage of grinding mills in a mineral processing operation and to enable buyers to understand the best suitable grinding mill as per their specific needs.

As is quite evident (Marty knows that you know!), the ultimate objective of processing a mineral is to extract the maximum value from a raw material. There are two end results that one is trying to achieve - either to get a crushed product that can be directly used for industrial application or to recover a metal from a complex ore.

Before we proceed, let’s take a quick look at the top manufacturers of Grinding Mills.

Marty wants you to go back in time and take a look at the major player Metso whose roots can be traced as far back as the 1930’s when the first Hardinge Cascade Mills were built. In the 1970’s and 1980’s, Hardringe (then Koppers) was competing with other market leaders namely Dominion Engineering and Allis Chalmers. In 2001, brands including Allis-Chalmers, Hewitt-Robins, Nordberg, Hardinge, and Dominion were all combined under Metso Minerals Svedala grinding range. Today, Metso is the biggest player in the grinding equipment space and competes with FLSmidth, CITIC, and ThyssenKrupp.

Minerals Processing Framework (diagram)

Stage 1 – Drilling

This is the stage where it all begins. A rock cutting process, drilling sets the stage for the next steps in the mineral processing operation. Be it surface or underground deposits, we are mining our way to the next stage!

Stage 2 – Crushing & Screening

So now the size reduction of our ore begins! In terms of tonnage, this is the biggest process in the processing cycle. Different types of crushers are used as per the various established parameters of size, shape, and strength. Jaw Crushers, Roll Crushers, Gyratory Crushers, Cone Crushers are some of the crushers that are used in this process.

But wait! This is not an article on Crushing & Screening (coming soon!) so why are we talking about crushing? Well, crushing and grinding in various combinations are used to maximize the value in size reduction so we wanted to give you a little peek into this stage. But with no further ado, let’s move on to the third stage and the one that brought you here – Grinding!

Stage 3 – Grinding

Following the first controlled size reduction stage of crushing, we want to further reduce our ore to obtain a mineral powder. There could be various reasons for reducing the size – we might want to free the individual minerals trapped in ores or simply expose the mineral to a leach solution. Grinding can be either Dry or Wet. Dry processing (Marty says that you would have guessed!) either does not require water for processing or no water is permitted in the processing of the ore. Wet grinding is generally preferred because of lower power consumption and higher mill capacity. Dry grinding must be used where wet grinding is feared to change the physical or chemical structure or/and if a higher percentage of fines is required.

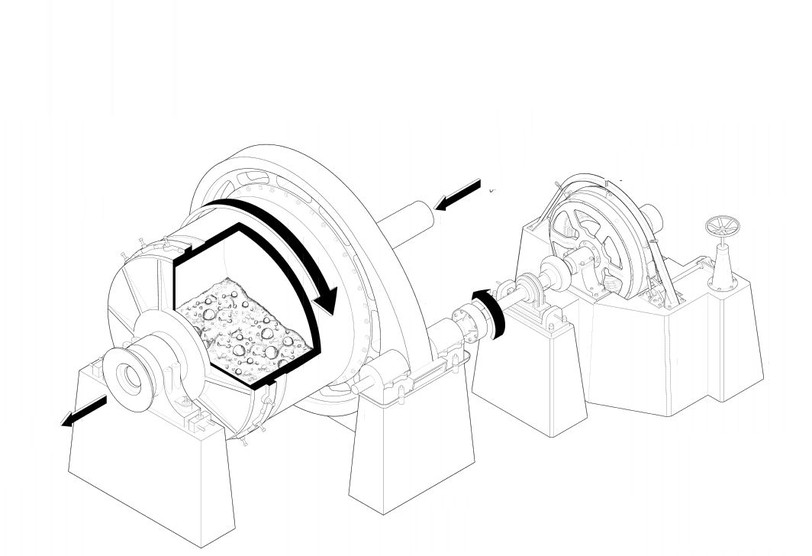

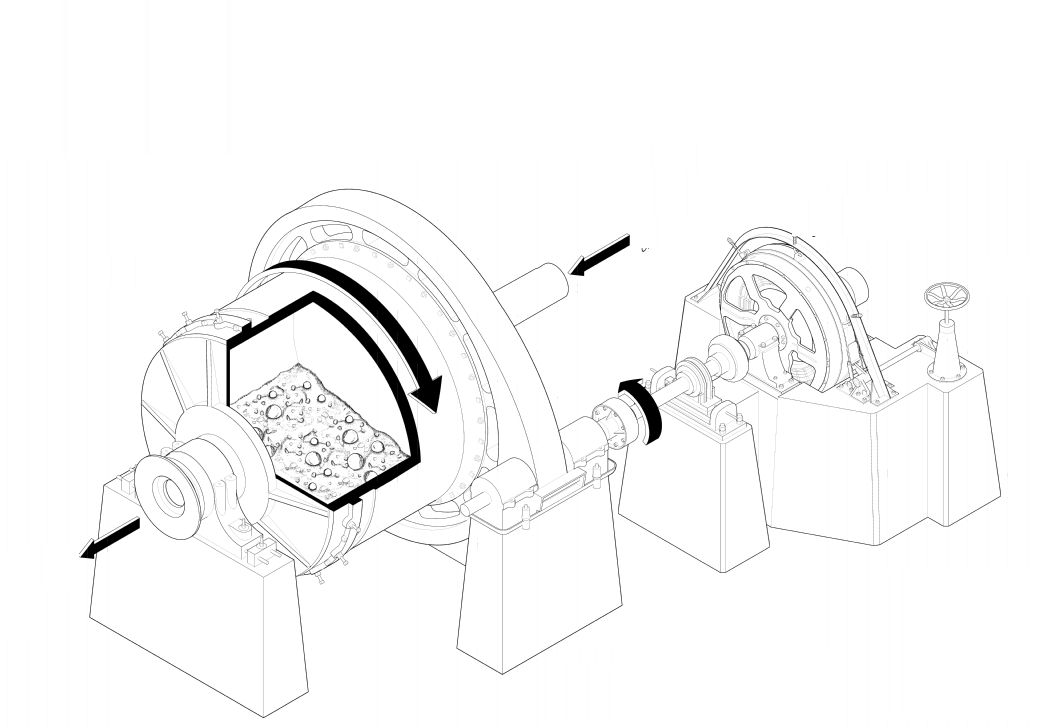

How does grinding work? What are the forces in play? Imagine (Marty says “wait, see the diagram below!”) a cylindrical steel vessel with an ore and a grinding medium moving inside the mill, the rotating drum lifting this material and finally breaking the ore into a specified product.

Further, the grinding mills can be categorized into three major types – rod mills, ball mills, and SAG mills. So, which one is for you? Well, the answer essentially lies in the feed size and the required product size.

Semi-Autogenous Mills/ SAG Mills (primary grinding mill) – these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in finer particles. Feed size range is 400 mm / 16 in and product size of 75 microns. The product of the large SAG grinding is either a finished size ready for processing, or an immediate size for further grinding. Examples include use in gold, copper and platinum mines with applications also in the lead, zinc, silver, alumina and nickel industries.

Rod Mills – these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles. Rod mills can accept feed up to approximately 50 mm. (2 in.) and produces the product size of 600 microns. Rod mills are more suitable for breaking up large pieces of ore due to the heavy weight of the rods. Examples include large pieces of rock, coal, copper or other media. The product will be a fine aggregate for use in building materials and chemical industries. Also, desirable when grinding coarse-grained ores.

Ball Mills – these use balls for grinding media breaking the coarse feed materials by impact and attrition into extremely fine powder. Ball mills use a feed of about 15 mm (½ in.) or finer and product size is very fine with no actual grind limit indicated. Examples include use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. Widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and non-ferrous metals.

More questions? Read on...

How long do Grinding Mills last?

As a matter of fact, well-maintained mills will give you dependable and hassle-free operation year after year. Capacity or product size remain unaffected by any wear on the grinding surfaces. Very little upkeep is required and inactivity has a negligible effect if any. (Marty says we have serviced 40-50 years old mills and received client’s feedback of “Excellent Condition!” each time).

Which parts commonly wear out? The internal shell liners and headwear liners. These are parts that are installed to protect the main structure of the grinding mill and are replaced as they wear out. Liners are available in various materials and several designs. Most commonly used liners are made of hardened steel, rubber, and ceramic.

Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new liners. Ball Mills commonly use rubber liners while steel liners are mostly used for larger SAG/AG/Ball mills. Marty says liners are prone to metal or rubber contamination and should be replaced to ensure higher efficiency.

At Savona Equipment, as part of the reconditioning process, we also replace liners providing you with a fully operational mill. All our refurbished grinding mills are inspected and supplied ready for service.

Still not sure which grinding mill is the best fit for you? Contact us and we will be happy to assist you!