Sell Your Equipment Financing - Apply now

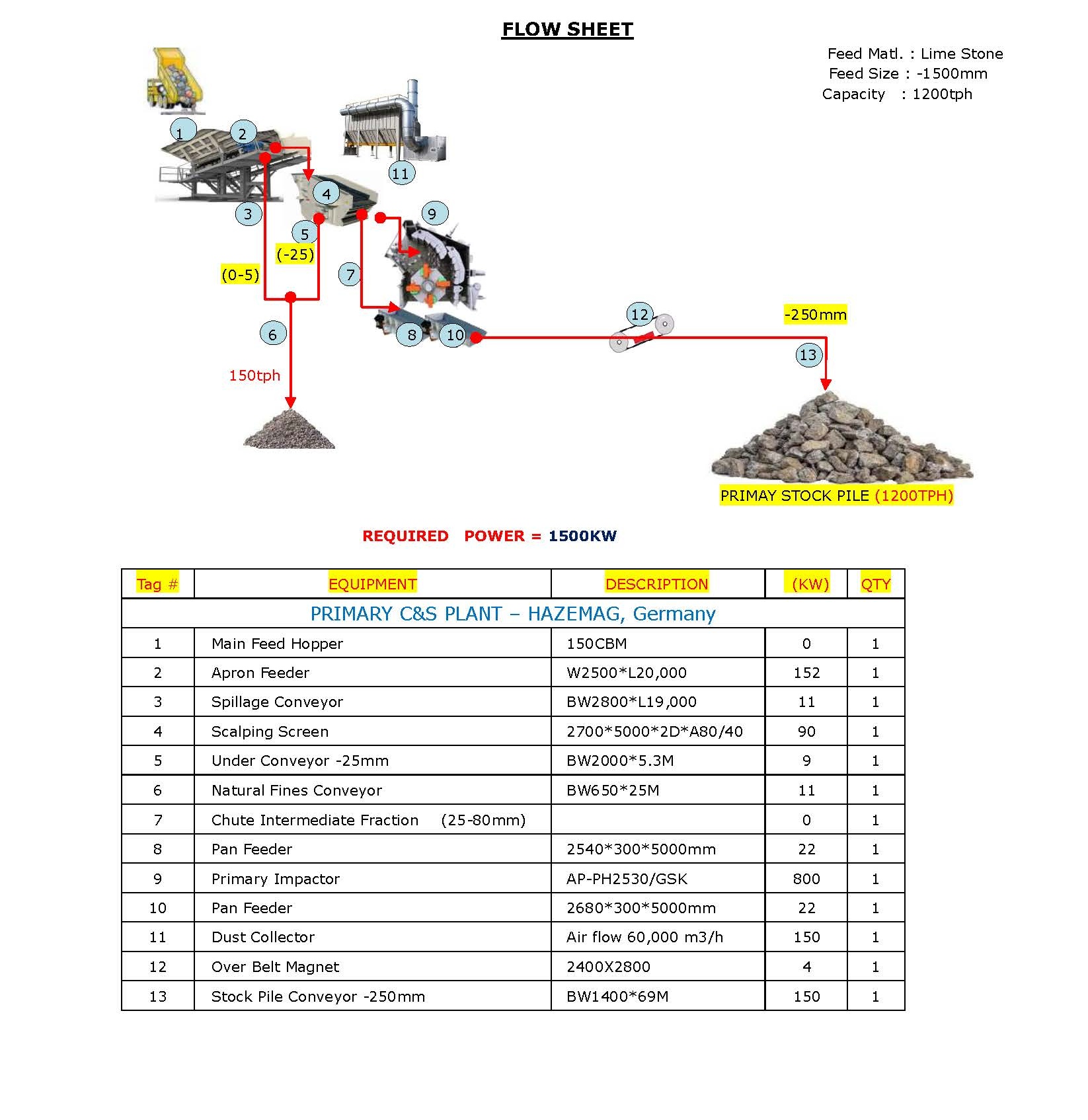

Hazemag 1300 TPH Stationary Primary Crushing Plant ID: 1390432

Hazemag Stationary Primary Crushing Plant

- Make: Hazemag

- Condition: Never Used, Company Packed

- Crusher: HPI 2530

- Material : Concrete, Reinforced Concrete, Construction Demolition Waste, Limestone

- Feed Size (CDW): 0 – 1100 x 800 x 600 mm with 30% <60 mm

- Total Plant Capacity : 1300 TPH

- Primary Crusher Capacity : 1000 TPH

- Plant Product Size : <60 mm (95%)

- Bulk Weight CDW : 1,200 – 1,600 kg/m³

- Moisture Content CDW : Max 5%

- Operation : 20 hrs. x 7 days

- Ambient Temperature : 5-55°C

- Dust Collection Volume : 60,000 m³

View Spec Sheet Below - Technical Description:

- Feed Hopper:

- Feed Material : CDW / Concrete / RCC

- Capacity : 150m³

- The Hopper is a Steel Structure, designed for Feeding with an Off-Load Truck

- Sonar Level Control:

- An Ultra-Sonic Level Detector monitors a minimum level of material in order to protect the Apron Feeder against the direct impact of the feed material.

- An Ultra-Sonic Level Detector monitors a minimum level of material in order to protect the Apron Feeder against the direct impact of the feed material.

- Apron Feeder: (Type PBRK 25/200–D7)

- Design : Tractor Chain Type D7

- Centre Distance: 20,000mm

- Width : 2,550mm

- Inclination : 23° Degrees

- The Apron Feeder is made up of a base frame with skirt boards and a drive unit. The Drive Unit consists of a Tractor Chain with Power Transmission with a Planetary Gear Reducer and Coupling. The Speed is Controlled by Frequency Converter.

- Skirting of Apron Feeder

- Spillage Conveyor for Apron Feeder

- Double Deck Eccentric Shaft Screen (Type 2700/5000)

- Screen Width : 2,700mm

- Screen Length : 5,000mm

- Sizing:

- Upper Deck : 60mm

- Lower Deck : 10mm

- Skirting of Double Deck Screen

- Chute for Fine Fraction Passing the Double Deck Vibrating Screen

- Chute for Intermediate Fraction

- Belt Conveyor Type : 2000/7000 (For Sand Transport)

- Belt Width : 2,000mm

- C-C Spacing: Approx. 7,000mm

- The Belt Conveyor can be operated reversible in both directions.

- Stockpile Belt Conveyor Type: 650/25000 (for Sand Transport)

- Belt Width: 650mm

- C-C Spacing: Approx. 25,000mm

- This Stockpile Belt Conveyor for Sand Transport Discharges the Sand to the Stockpile.

- Crusher Inlet Hood/Chain Curtain/Water Sprinkling System:

- The Crusher Inlet hood is Welded Steel Plate Design. The Chain Curtain is connected to the Crusher Inlet Hood. The Water Sprinkling System is used for Dust Suppression.

- The Crusher Inlet hood is Welded Steel Plate Design. The Chain Curtain is connected to the Crusher Inlet Hood. The Water Sprinkling System is used for Dust Suppression.

- Crane:

- This Crane consists of a Crane Beam and an Electric Hoisting Unit.

- Crane Capacity: 2,000 Kg

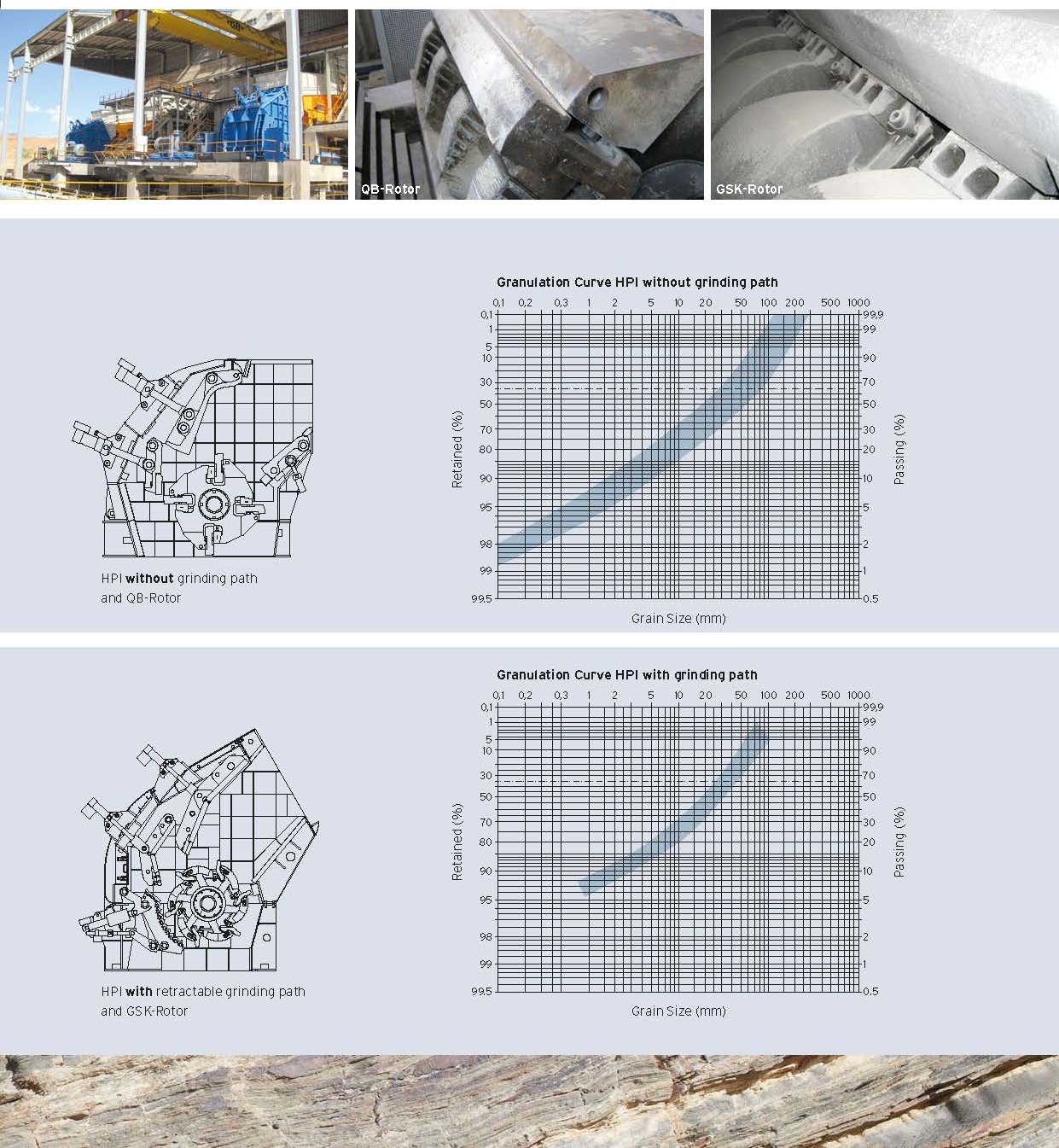

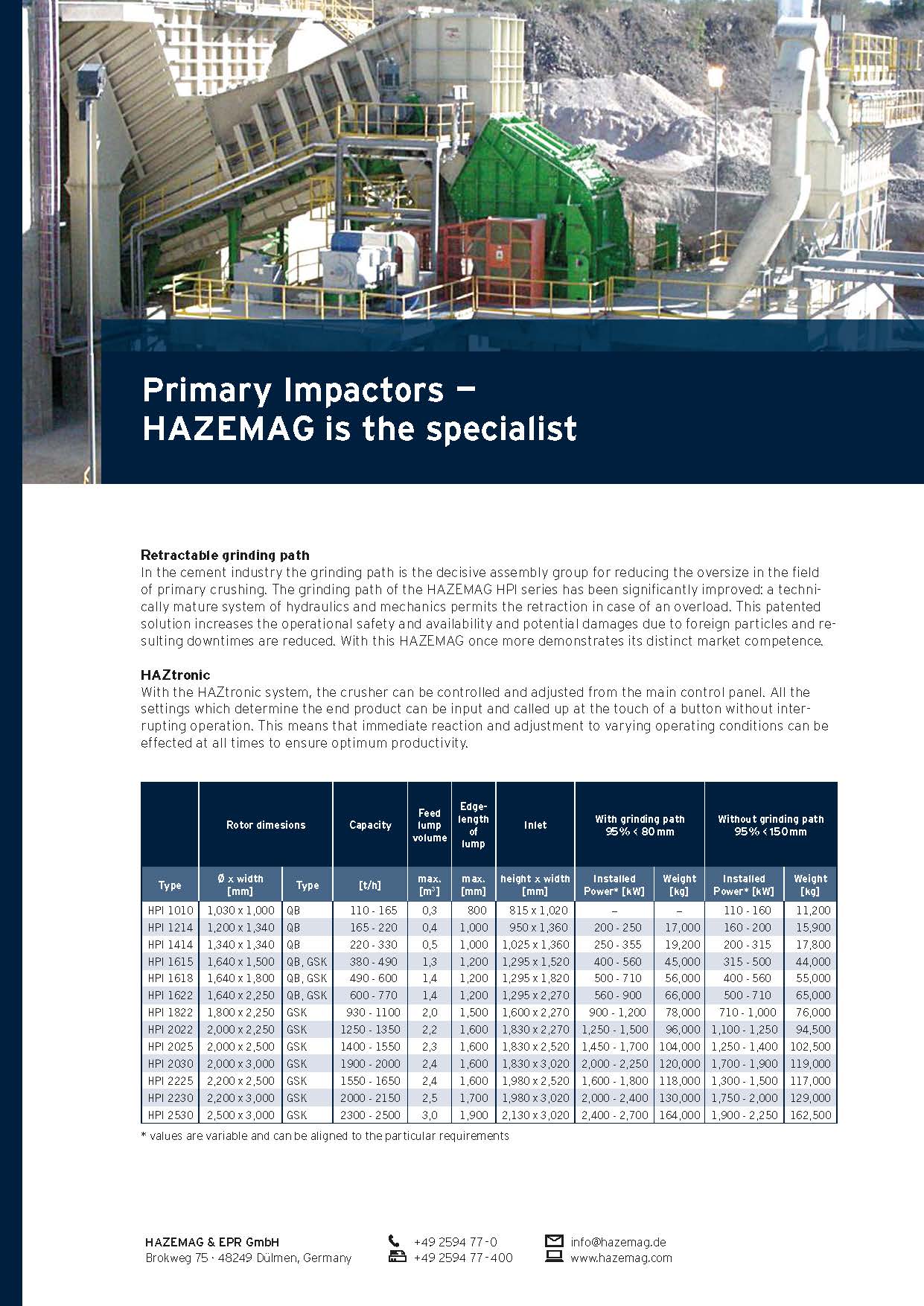

- Impact Crusher (Type AP-PH 2530/GSK)

- Crusher Design: Single Rotor Impact Crusher

- Rotor Design: GSK Rotor, Designed for Recyling

- Rotor Diameter: 2,500mm

- Rotor Width: 3,000mm

- Gap Setting System: Front & Rear Apron : Hydraulically

- V-Belt Drive System, Incl. transmission

- LV Motor:

- Power Output: 800kW

- Voltage: 400 Volt

- Frequency : 50 Hz

- Motor Specially for Crusher Drive with Amplified Bearings and Suitable for Heavy Starting.

- Crusher Discharge Chute:

- The Crusher Discharge Chute Underneath the Crusher is Connected to the Discharge Vibrating Feeder. Its Comprised of a Rugged Steel Plate Design.

- The Crusher Discharge Chute Underneath the Crusher is Connected to the Discharge Vibrating Feeder. Its Comprised of a Rugged Steel Plate Design.

- Primary Vibrating Feeder (Type 2.7/5.0):

- The Primary Vibrating Feeder is Mounted Underneath the Crusher Discharge Chute and ensuree a constant discharge to the Connected Secondary Vibrating Feeder.

- The Primary Vibrating Feeder is Mounted Underneath the Crusher Discharge Chute and ensuree a constant discharge to the Connected Secondary Vibrating Feeder.

- Secondary Vibrating Feeder (Type 2.7/5.0):

- The Secondary Vibrating Feeder is mounted underneath the Crusher Discharge Chute in Connecting to the primary Vibrating Feeder and ensures a constant discharge to the connected belt conveyor. In addition the discharge side of the Vibrating Feeder is antimagnetic in order to install the First over Belt Magnet at this position.

- The Secondary Vibrating Feeder is mounted underneath the Crusher Discharge Chute in Connecting to the primary Vibrating Feeder and ensures a constant discharge to the connected belt conveyor. In addition the discharge side of the Vibrating Feeder is antimagnetic in order to install the First over Belt Magnet at this position.

- First Over Belt – Magnet (Type 240/280):

- Magnet Width: 2,400mm

- C-C Spacing: Approx. 2,800mm

- This Over Belt Magnet consists of a Fixed Magnet with a Revolving Belt Conveyor with Vulcanized Cross-Bars. The Belt Drive is driven by means of a Hollow Shaft Geared Motor.

- Air Pulse Filter System for Crushing Unit:

- Air Volume : 60,000 m³/h

- Operation : Suction

- Set of Accessories for Air Pulse Filter including;

- Compressor

- Hoods, Fitting and Adapting Pieces

- Regulating and Manual Valves

- Ventilator

- Piping

- Second Over Belt – Magnet (Type 95/120):

- Magnet Width : 950mm

- C-C Spacing: Approx. 1,200mm

- The Over Belt Magnet consists of a Fixed Magnet, with a Revolving Belt Conveyor with Vulcanized Cross-Bars. The Belt Drive is driven by means of Hollow Shaft Geared Motor.

- Stockpile Belt Conveyor (Over Tunnel) Type: 1400/69000:

- Belt Width: 1400mm

- C-C Spacing: Approx. 69,000mm

- This Stockpile Belt Conveyor Handling the Throughput from Impactor and Oversize from Screen to the Main Stock Pile

- Electrical Equipment:

- The Electrical Equipment Comprises All Necessary Equipment to Run the Entire Plant includes:

- Process Control system (PLC) with operator station including:

- I/O system, process controller, software, Computer-Hardware, Network –Equipment.

- MV Switchgear including DC Power supply

- Transformer for LV system

- MV Liquid starters for MV Crusher Motor.

- MCC (Motor Control Cabinet) for all LV Motor, Including: Frequency converters, Contactors, Fuses, Main Switch, Illumination.

- LV Cabinet for Compensation

- Uninterruptable Power Supply (UPS)

- Sensor for Field Devices

- Digital Field Devices, Including: Control Devices, warning Devices, Safety Devices.

- Safety Key System for Crusher

- Illumination

- Process Control system (PLC) with operator station including:

- The Electrical Equipment Comprises All Necessary Equipment to Run the Entire Plant includes:

- Feed Hopper:

- Location: UAE

View More Crushing Plants

Image 1 of 46