Need this? Click here Have one? Click here

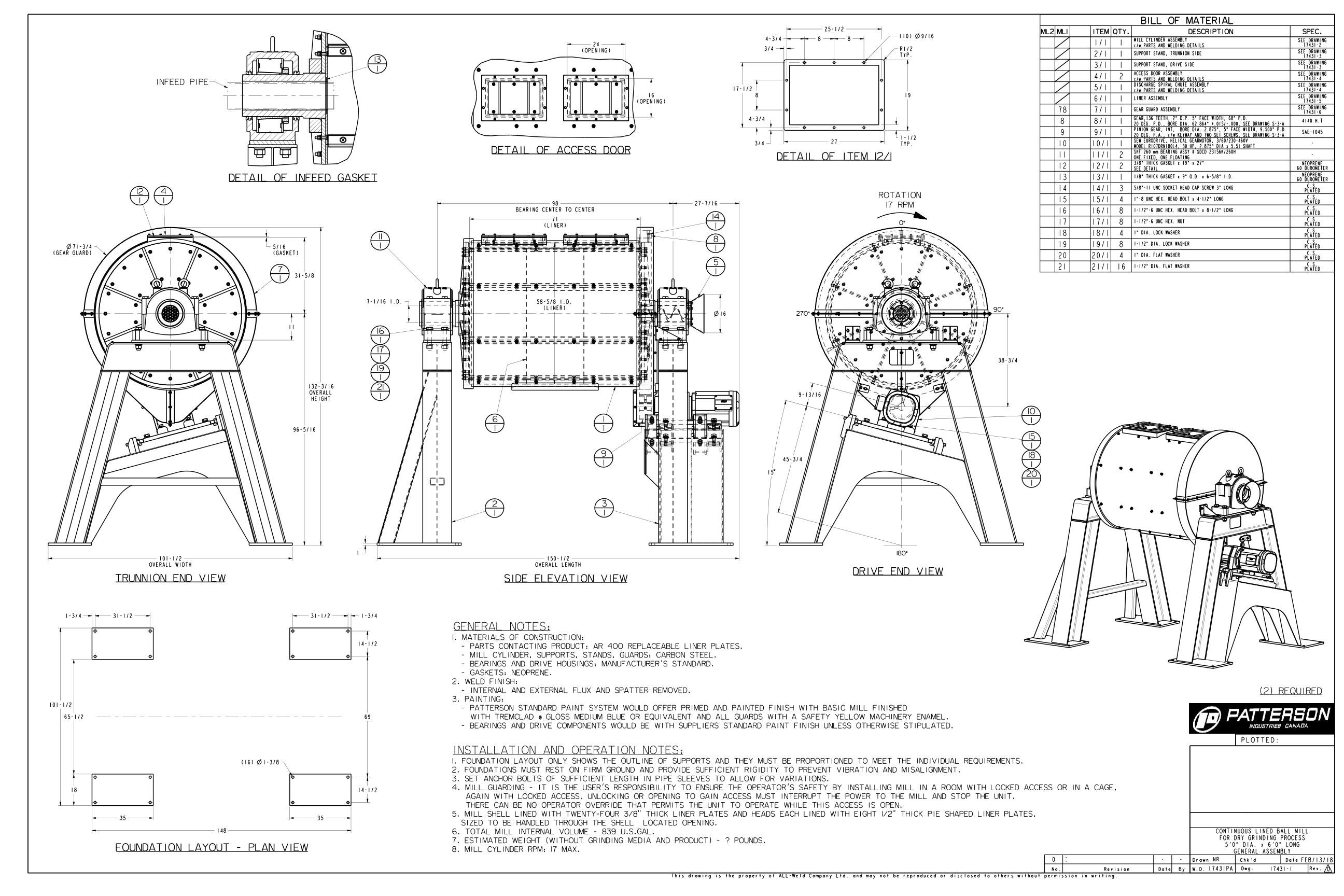

- 5 ft. 0 in. Diameter x 6 ft. 0 in. Long - Type "D" Non-Jacketed Steel Ball Mill

- Condition: New

Specifications

- Internal Mill Dimensions with Liner Plates Installed: 58-7/8 in. Diameter x 71-1/4 in. Inside Length

- Ball Mill Volume: Approx. 839 USG (112 cu.ft.)

Drive

- 30 HP

- 230-460 Volt

- 1725 RPM

- 3 Phase

- 60 Hz

- TEFC

- Enclosure

- Integrally Coupled to a Horizontal Parallel Shaft Helical Geared Reducer with Minimum AGMA Class II Gearing and Service Factor of 2.0 Minimum

- Output Shaft of the Gearbox is Installed the Pinion Gear Meshed with the Main Gear on the Mill Body

- Body Speed of the Mill is Approx. 17 RPM

Reducer

- SEW Eurodrive or Equal Horizontal Foot Mounted Parallel Shafted Helical Geared Unit with a Ratio of Approx. 14:1 Output Speed 125 RPM Full Load Motor Speed of 1750 RPM

- Mechanical Rating of 60 HP Minimum

Spur Gear

- Gear and Pinion Ratio 7.158 Approx.

- Class 40 Cast Iron or Equal Machine Cut Fine Tooth Helical Spur Gear

- 136 Teeth

- 2 D.P

- 20° Pressure Angle

- 5 in. Face Width

Pinion Gear

- SAE 1045 or Equal Forged Steel Machine Cut Fine Tooth Heicsl Pinion

- 19 Teeth

- 2 D.P

- 20° Pressure Angle

- 5 in. Face Width

- Body Speed Approx. 17 RPM

Mill Guarding

- Comes Supplied with Full Type Split Gear Guard

Mill Interior Finish

- Mill Shell Lined with 24 x ¼ in. Thick Liner Plates

- Head Each Lined with 8 x 3/8 in. Thick Pie Shaped Liner Plates

- Liner Plates Retained in Place by 8 x Bolted-In Lifters/Retainer Bars

- Inlet and Mill Trunnion with Lifter Inside Diameter to Suit 6 in. Diameter Feed Auger and Ball Retaining Screen

Mill Cylinder

- Fabricated Weldment Consisting of Fabricated Steel Ribbed Heads and Carbon Steel Shell

- Opening for Charging of the Mill is Cut in the Shell and Door Frame is Welded Around Opening

- Opening: 14 in. x 20 in.

- Allow for Installation of Liner Plates

- Fabricated Steel Mill Heads Have Bearing Trunnions

- Some 10 in. Diameter

- Drive Head has an External Flange

- Main Bull Gear is Mounted

Cylinder Access Door

- Fabricated Steel Grinding Door Complete with

- 3/8 in. 60 Durometer Neoprene Rubber Gasket

Trunnion Bearings

- Cast Iron Split Cap and Bottom Housing with

- Poured ASTM Alloy Grade 7 Babbitt

- Machined

- Grease-Grooved Surface

- Top Caps have a Cavity for Filling with Bearing Block-Type Brick Grease-Grooved Surface

- Bottom Halves have Externally Cast Spherically Contoured Body Seats into their Counterpart

- Bearing Sockets and Bearing Socket Brackets are Bolted to the Support Stand

- Bearings: 10 in. Diameter with

- Heavy Duty

- SKF or Equal

- Adaptor Sleeve Mounted

- Spherical Roller

- Self Aligning Pillow Block Bearing with

- Cast/Ductile Iron Bodies and Standard Double Lip Seal

Support Stands

- Fabricated Weldments using

- Standard Structural Steel and Plate Sections

- Stands are Designed for 66 in. Clearance Between Mill Cylinder and Floor

- Stands are Upper Pad Surface for Bolting Together with Bearing Socket Bracket

- Location: Western USA

View more Ball Mills

Sold

Image 1 of 1